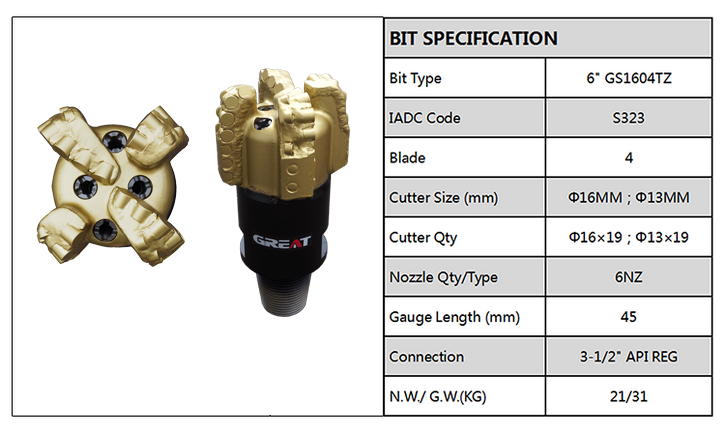

GS1604T

In clay/shale drilling environments, where balling of PDC cutters/blades limit the bit performance seriously, the bit balling triggers lower ROP while drilling, swabbing while triping.etc

In conventional drilling ,the operators lower the RPM &WOB,enhance the SPM to combat bit balling with sacrificing the drilling efficiency.

With investigating in balling bit in amount of wells ,the solution was found by the GREAT engineers, they designed an anti-balling bit, the GS1604T PDC bit.